Learn how LeTote used Nerves to build a web-based kiosk system to drive warehouse productivity

The Concept

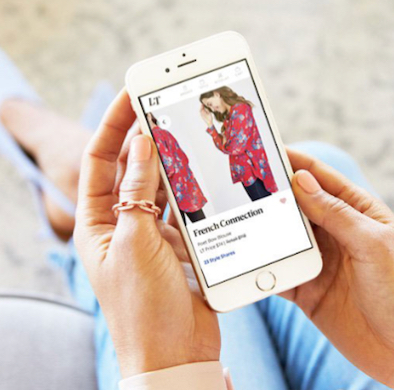

Le Tote is a personalized clothing rental subscription service that needed a better way to track inventory and keep the company’s warehouse operating smoothly.

Surprisingly, there are not a lot of off-the-shelf solutions for warehouse management that accommodate for a rental model, where most of the items that leave the warehouse return. Le Tote needed to account for each clothing item that it rents out and monitor it throughout its lifecycle, which includes activities like re-steaming, pressing, and finally repackaging the garments.

Le Tote previously kept track of each item through barcode scanners, but this method wasn’t meeting Le Tote’s high standards for efficiency. Each garment has many touchpoints in its warehouse lifecycle, and the barcodes on each item of clothing were tiny, hidden on the back of the tag. Employees had to find and scan each individual tag at each touchpoint, adding a lot of unnecessary time to the production cycle.

How Nerves Helped

Le Tote hired Justin Schneck, co-author of the Nerves Project, as a Principal Hardware Engineer to help them use Nerves to develop and implement an RFID system to more efficiently track their product. And here’s where Nerves really shines: in addition to building this custom RFID solution, Le Tote used Nerves to build web-based kiosk systems to guide employees with all kinds of tasks all across the warehouse.

Nerves made developing the kiosk system incredibly easy because it helps apply the agile principles of web development to hardware. Justin and his team were able to use their web developers as embedded engineers by having them create web apps which would then be run on top of a Chromeless Chrome window that’s rendered on a device’s display. This helped them to make the most of their existing people and resources, rather than hunting for rare C++ developers to complete the embedded work they needed done.

This approach also allowed Le Tote to then create rapid prototyping mechanisms. They were able to replace a third-party vendor for pack stations and receiving workstations within months by being able to rapidly develop and iterate on their own software and deploy it so quickly and easily.

The Results

With Nerves, Justin and the Le Tote team were able to build systems and processes that made the warehouse function more efficiently. Clothing items can now be tracked more quickly and reliably throughout their lifecycles, and employees are able to move throughout the warehouse to complete tasks in a more streamlined manner.

Finally, the system reliability and uptime of the warehouse was dramatically increased by switching from Windows to Nerves alone.